Shrimp / Fish Processing Machineries

Our Machines are completely made in Food Grade Stainless Steel. Used for clean washing and accurate grading of Head-on, Headless – Shell on, PUD types of Shrimps & Prawn. The average capacity under standard test condition ranges from 450 kg to 500 kg/hr. Six different grades can be collected on a single machine at a time.

Click on Below Links to Know more about machines

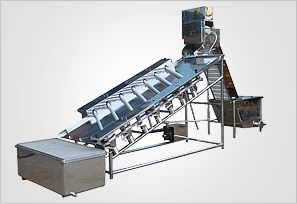

Used for clean washing and accurate grading of Head-on, Headless – Shell on, PUD types of Shrimps & Prawn. The average capacity under standard test condition ranges from 450 kg to 500 kg/hr. Six different grades can be collected on a single machine at a time. Machines are completely made in Food Grade Stainless Steel.

Used for clean washing and accurate grading of Head-on, Headless – Shell on, PUD types of Shrimps & Prawn. The average capacity under standard test condition ranges from 450 kg to 500 kg/hr. Six different grades can be collected on a single machine at a time. Machines are completely made in Food Grade Stainless Steel.

- Feeder Conveyor

- Blanching/ Cooking Conveyor

- Cooling & Draining Conveyor

- Vibrator Feeder

- I.Q.F Conveyor with Refrigeration

- Spray Glazer

- Spray Glazer

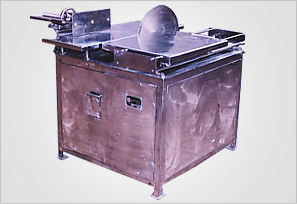

Used for slow & uniform stirring of the approved chemicals with approximately 600 kg of Shrimps/ Prawn. Machines are completely made in Food Grade Stainless Steel.

Used for slow & uniform stirring of the approved chemicals with approximately 600 kg of Shrimps/ Prawn. Machines are completely made in Food Grade Stainless Steel.

The Squid Tubes are placed manually on a Food Grade Belt and are cut mechanically into rings.

The Squid Tubes are placed manually on a Food Grade Belt and are cut mechanically into rings.

Used for slicing frozen Fish meat into any required size & shape. Available in both Benzo blade and Circular blades.

Used for slicing frozen Fish meat into any required size & shape. Available in both Benzo blade and Circular blades.

Used for the instant manual blanching of Shrimps/ Prawn/ Squids. The water is electrically heated by Bobbin Heaters and the temperature can be regulated electronically.

Used for the instant manual blanching of Shrimps/ Prawn/ Squids. The water is electrically heated by Bobbin Heaters and the temperature can be regulated electronically.

The Sea-catch is directly dumped into the Tank and clean hygienic product is conveyed out of the Tank after rigorous washing done by the heavy duty blowers fitted inside the Tank.

The Sea-catch is directly dumped into the Tank and clean hygienic product is conveyed out of the Tank after rigorous washing done by the heavy duty blowers fitted inside the Tank.

Used for continuous de-frosting of the meat slab from the Trays/ Pans after the trays are removed

Used for continuous de-frosting of the meat slab from the Trays/ Pans after the trays are removed

from the Plate Freezers.

Used in at a value addition stage the Shrimps/ Prawn are manually de-headed and are conveyed systematically so as to collect the waste in one end and the main meat at the other end.

Used in at a value addition stage the Shrimps/ Prawn are manually de-headed and are conveyed systematically so as to collect the waste in one end and the main meat at the other end.

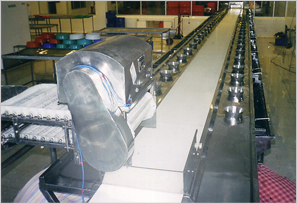

Used in the manual setting of the Shrimps/ Prawn into the trays. The Raw material basins are collected at one end and the set trays are collected on the other end.

Used in the manual setting of the Shrimps/ Prawn into the trays. The Raw material basins are collected at one end and the set trays are collected on the other end.